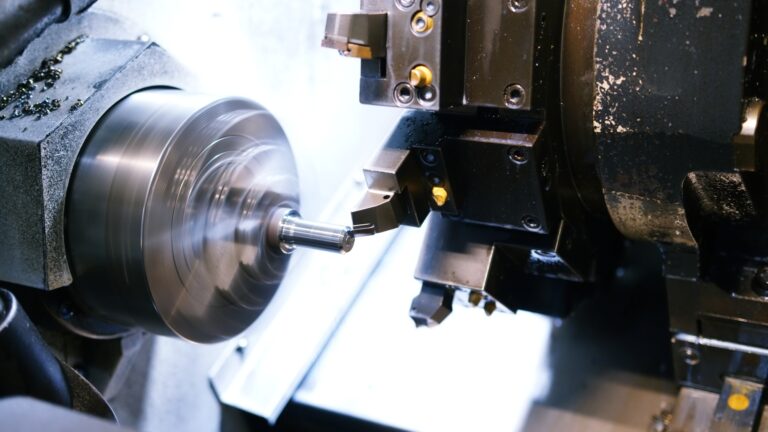

CNC Turning

Precision turning with modern lathes equipped with live tooling. Bar feeder automatics allow for continuous and efficient production.

CNC Milling

13 CNC milling machines, including 4-axis models and a large two-pallet horizontal center. Machining of complex shapes with the highest accuracy.

Grinding

Final processing ensuring high dimensional precision and surface smoothness.

Thread Rolling

Efficient and fast thread forming in both small and large series, guaranteeing component durability.

Die Forging

Vertical presses and a RUTA press enable efficient forming of high-strength metal components.

Welding

Modern welding facility with 6 stations and robotic welding. We handle aluminum and stainless steels.

Heat Treatment

Two hardening plants: volume and induction. They ensure high durability and wear resistance of components.

Quality Laboratory

Dimensional inspection and strength testing. Guarantee of consistency and compliance with client documentation.

Prototyping and CAM/CAD

Design support, rapid 3D printing, and computer-aided production management systems. Shape and cost optimization.